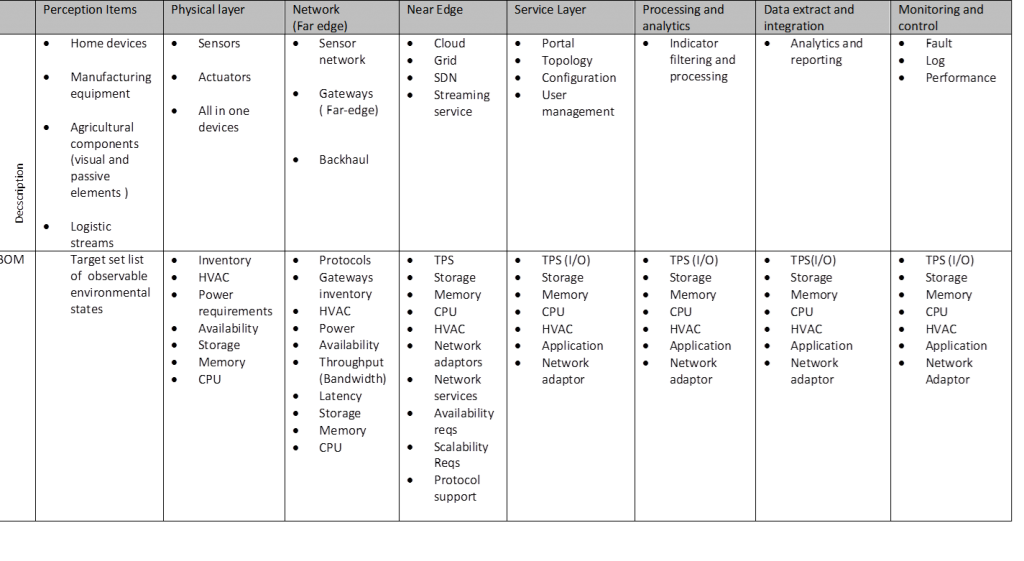

Building an IoT BOM takes into account several areas of interest which can be roughly grouped as follows:

- The items to be perceived/sensed

- Physical interaction layer: manufacturing sensor, design time & run time equipment, home device sensors

- The network ( far-edge) which carries perceived data for processing, and interaction messages for controlling the items to be perceived

- The near-edge device(s), or cloud interface, which support processing in the data and control layers as well as grid/cloud computing and software network evaluation

- Services layer including configuration ( Network and indicator ), user management,

- Processing and analytics

- Data extract and integration

All of these components have a certain energy footprint to be taken into account in the design of an IoT system and subsequent BoM relating to the evaluation/measurement, or manufacturing chain.

Once the complete E2E operational footprint is taken into account it shall be possible to offset operational costs against savings to be gained as value through the implementation.

The IoE/BoM should include the necessary measurement and monitoring components providing capability of capturing operational information, and comparing with target metrics.These management components are added as a sub-set of the total processing components listed above.

Finally, the operational profile should include the people necessary to run the system in an acceptable manner within the stated SLA’s. This is a critical aspect of evaluation in assessing comparative options in conducting the process in some other manner ( ie. land based, versus aerial remote sensing ).

Once the necessary levels of QoS are defined, another pass through the design is necessary to ensure that performance characteristics meet stated objectives, at least on paper/specifications and based on selected tests.

At this stage a pilot study to verify operational characteristics, and feedback results can be carried out, ensuring that strategic as well as operational objectives are met, presenting an opportunity of testing measurement and monitoring results & failure conditions, generally applying operational readiness & security procedures, ensuring the system meets initial specifications.

The verification process can now begin, ensuring that test results are in keeping with specific technical and regulatory constraints as specified in earlier phases.